Tower Seating provide one stop manufacturing solution for bus seat, coach seat and marine seat,.

All process in house、Experienced Engineers and Skilled Workers、Contract Manufacturing、Access to Laboratory

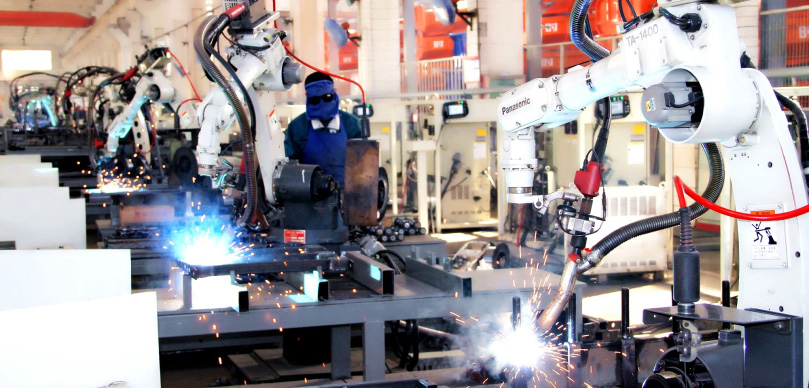

1. All process in house

We have all process in house such as laser cutting, tube bending, stamping, deep draw, frame welding, plastic injection, seat foaming, power coating, seat cover sewing, seat assembly, which help us make completed prefect seat in house at low cost with quick delivery time.

2.Experienced Engineers and Skilled Workers

Tower Seating is Employee-Owned company, which means all employee can benefit from the growth of the company, and most of the employee have been work here for many years, which give us confidence everyone it’s the expert of their position. And everyone is improving together with the company.

3.Contract Manufacturing

We are contract manufacturer, customer can get details in various stages of production, the process just like produce the products in your own facility but with much lower cost. Customer own all the design, tooling, and procedure of the production, customer have all the right just as produce in customer own facility. Online videos can connect if request, you can watch all process just as you on site.

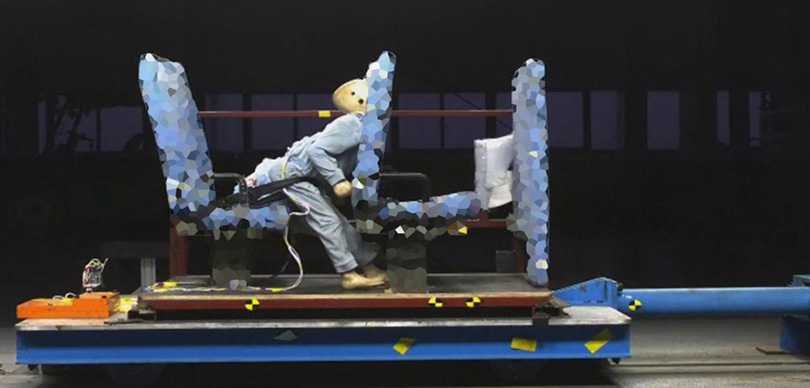

4. Access to Laboratory

Safety is the most important point, we have cooperated laboratory, which can run all kinds of testing like E-MARK, FMVSS 207/210, ADR68.